Vapor Encroachment Screen (VES)

Evaluating a vapor intrusion potential typically starts during the completion of the Phase I ESA which includes a vapor encroachment screen (VES). The screen makes a preliminary evaluation of the potential presence of chemicals of concern (COC) that may migrate as vapors into the vadose zone of a property as a result of contaminated soil and/or groundwater on or near the property.

Vapor Encroachment Condition (VEC)

The goal of conducting a VES on a parcel of property is to identify a vapor encroachment condition (VEC), which is the presence or likely presence of COC vapors in the vadose zone of the target property caused by the release of vapors from contaminated soil and/or groundwater either on or near the target property.

Sampling

When a potential VEC is identified, sampling is usually completed to confirm or deny the presence of the VEC. Sampling varies by state but usually includes one or more of the following:

- Sub-Slab Soil Gas Sampling

- Vapor Pin Installation (directly beath slab)

- Groundwater Sampling

- Indoor Air Sampling Canisters

Building Control Technology

A Sub-Slab Depressurization System (SSDS) fan and vent is being installed (roof mount example).

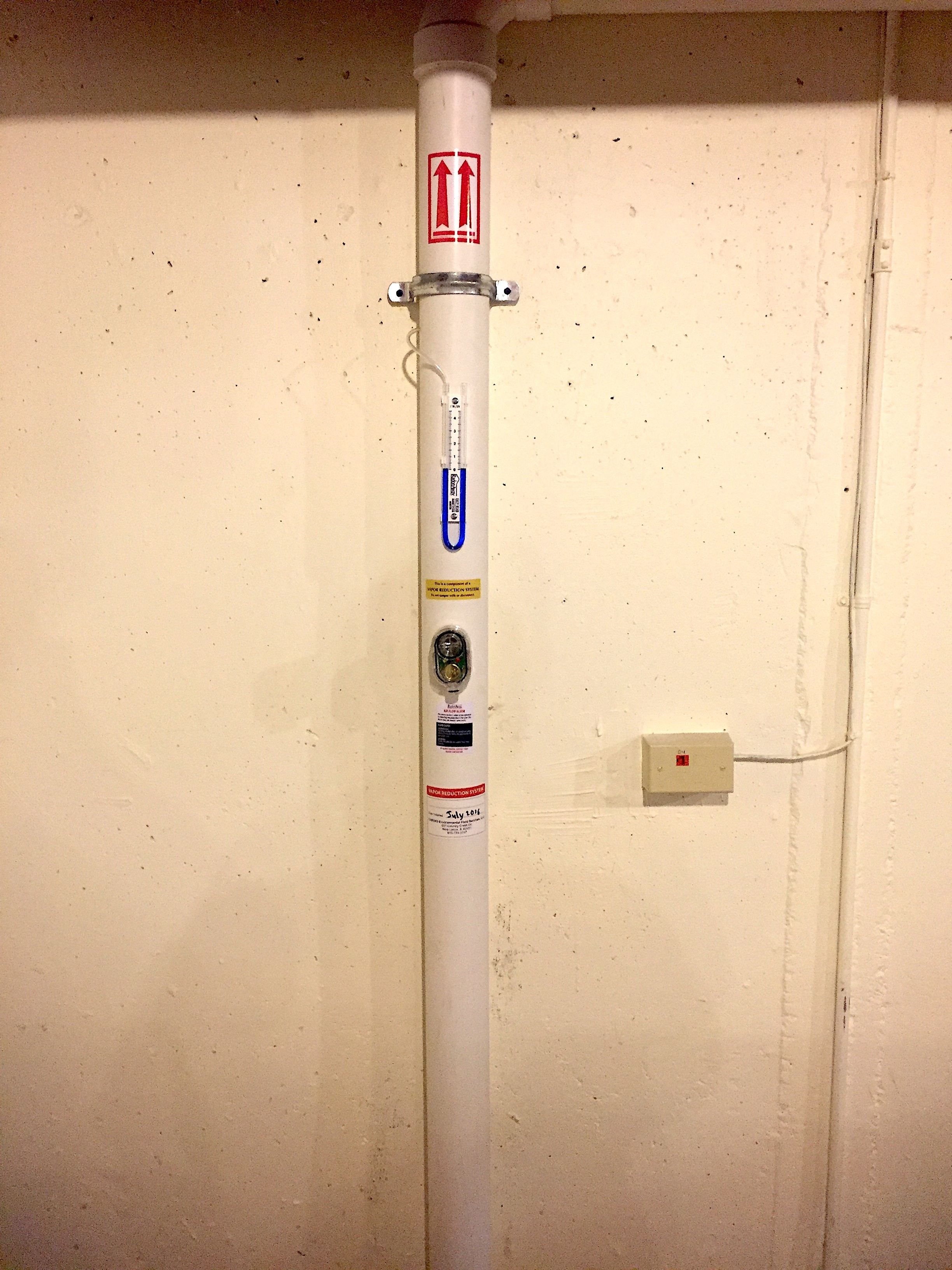

When vapor intrusion of chemicals into the building is occurring or has the potential to occur, mitigation will be needed to prevent exposure to building occupants. In these cases, a Building Control Technology (BCT) system may be used to prevent vapor intrusion from occurring. The most widely used system for existing buildings is to retro fit the building with a Sub-Slab Depressurization System (SSDS). A SSDS system works by creating a negative air pressure beneath the floor of the building to remove any chemicals of concern prior to reaching the building interior. The system uses a network of small fans to maintain a negative air pressure under the floor of the building and vent the chemicals to the exterior away from any doors, windows, vents, or other potential intakes. The installation of these systems is very flexible and can be fitted to any building in a discreet manner.

Typical SSDS piping run with alarm and manometer to monitor vacuum pressure.

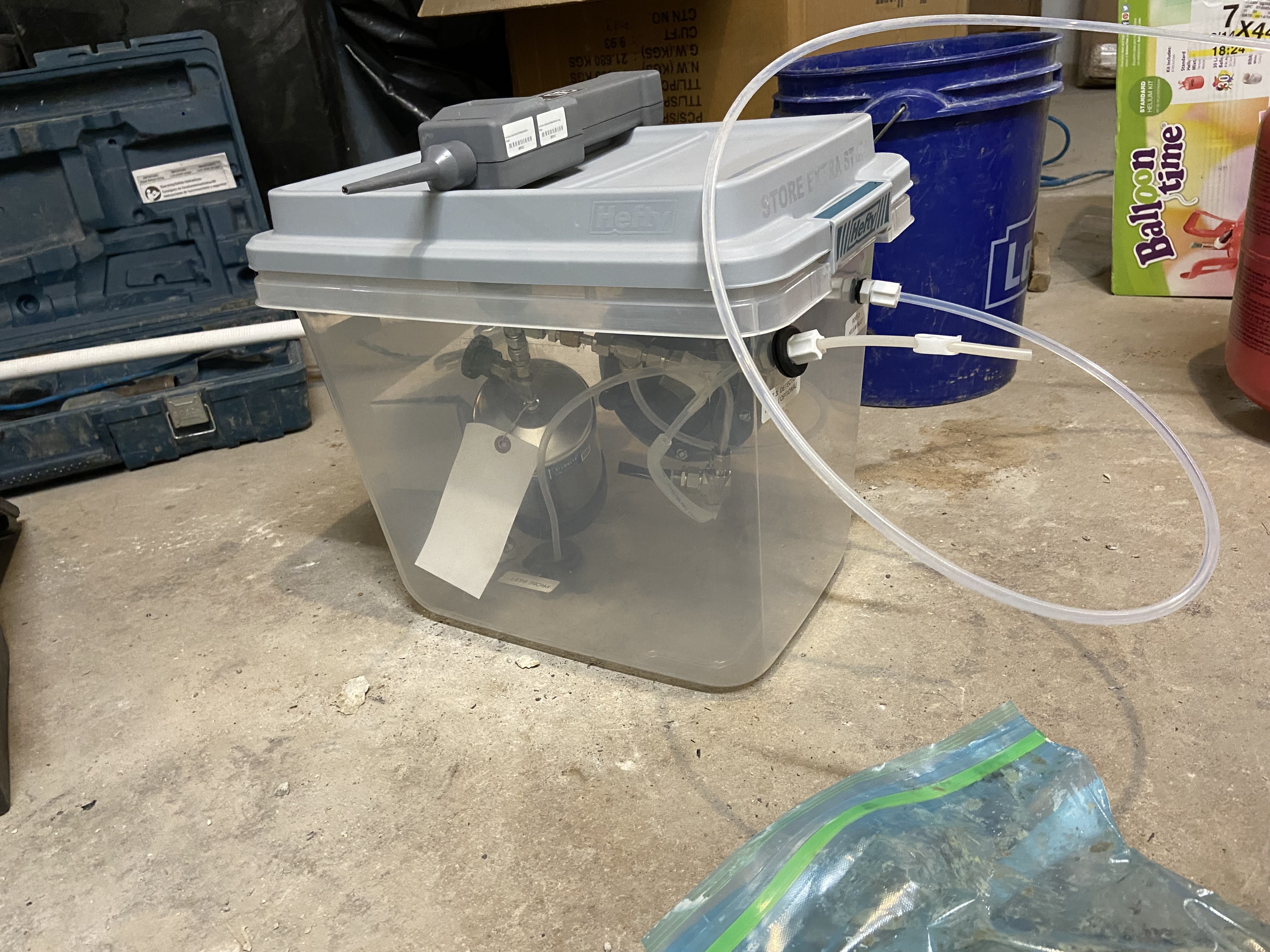

SSDS fans being installed (exterior entryway utility area).